SEM - EDS

Scanning electron microscope & energy dispersive x-ray spectrometer

Scanning electron microscopy (SEM) is a well-known non-destructive technique that uses an electron beam probe to analyse samples surface down to nano-scale. The scanning electron microscopes produce high magnification images with high resolution, a feature of which makes them suitable tools for a wide range of applications in numerous fields of science and industry

The scanning electron microscope allows to image specimens at high magnifications using a number of different contrast mechanisms .Magnification ranging from 20X to approximately 30,000X, spatial resolution of (50 to100 nm). The SEM analysis is critical in all fields that require characterization of solid materials, geological applications

Analytical SEM with EDS help to achieves fast analysis of material characterization and elemental analysis. SEM-EDS uses to analyses various type of samples and reveal critical information’s containing external Morphology, Chemical compositions, Crystalline structure, Multi-layer coatings/paints and orientation

The energy dispersive x-ray spectrometer (EDS) allows the collection of qualitative and quantitative information about the elemental composition of spots and regions of interest

Applications

Scale analysis

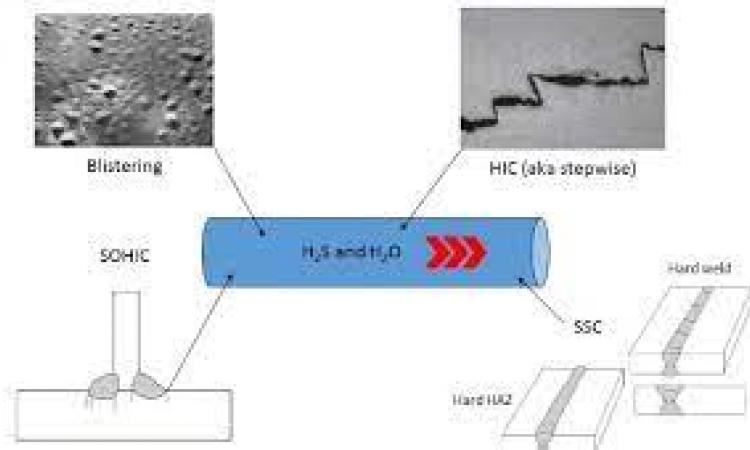

Corrosion product analysis

Failure analysis

Fractographic analysis

Identification of surface defect at micro and Nano level

Layer Thickness measurement of composite material and coating

Coating failure analysis

Biological sample analysis

Morphological identification of microorganisms

Trace element analysis

Particulate and contaminant on and within the material

Soil analysis for mineral identification

Particle and grain size measurement for soil

Assisting Air pollution particle analysis

Identification of wear particles found in production lines

Quality control of food product packaging and production

Sediment analysis of oil

failure analysis of electronics and integrated circuit