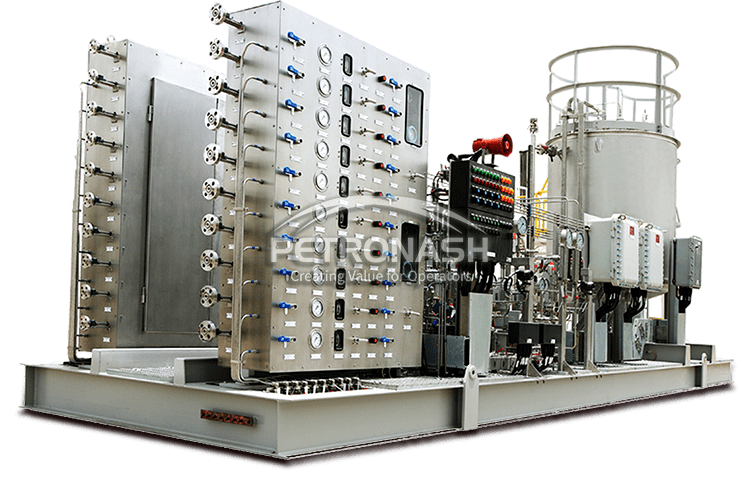

Chemical Injection Packages

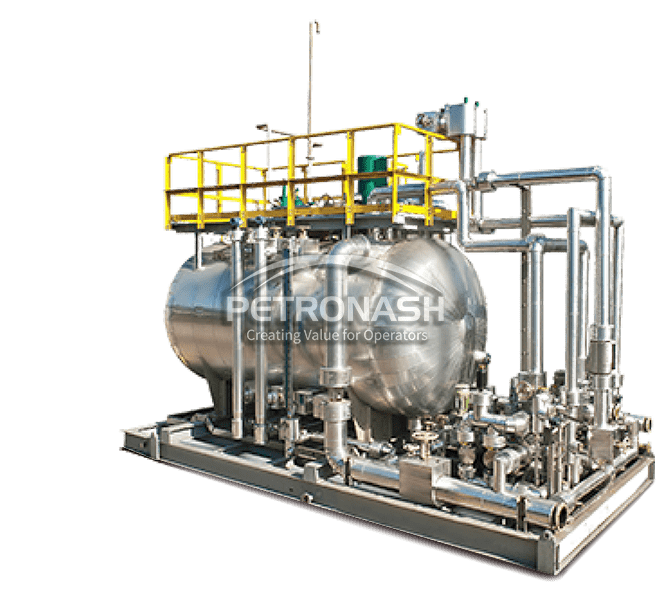

The Chemical Injection Package serves the purpose of injecting a precise and accurate amount of chemicals into a system with the required back pressure, either continuously or intermittently.

Our Chemical Injection Package Includes

The purpose of injecting the chemicals into a system is to protect the mechanical integrity of the system from accelerated corrosion and prevent scale formation. The aim is also to control hydrate formation, prevent oxygen induced corrosion, emulsion breaker for rapid and sharp separation of water from oil, reduce wax formation, water treatment, Odorization, foam control etc.

Petronash specializes in designing and manufacturing all types of chemical injection packages in line with customer requirements and that meet various industry standards.

Key Features of Chemical Injection Packages

- Design in accordance to customer requirements, application, standard and design codes

- Pump selection as per process parameter.

- Material selection as per material compatibility with chemical.

- Use of proven system components.

- 3-D Modelling of all packages.

- Design Validation.

- System Performance Guarantee.

- After Sales System Support.

- As a worldwide leader in the oil and gas industry, Petronash applies innovation in the manufacturing of different types of chemical injection packages, as described above.

Design Parameter Ranges Of Packages Constructed

Our scope includes :

Preparation of Fabrication Drawings

Procurement of Materials

Complete Fabrication at our works

Welding as per ASME Sec IX using qualified welders

All Non Destructive Tests

OUR SERVICES

Design, Engineering, Fabrication, Installation of Structural Steel, Piping, Pressure Vessels & Skid Packages.Constructional & Engineering

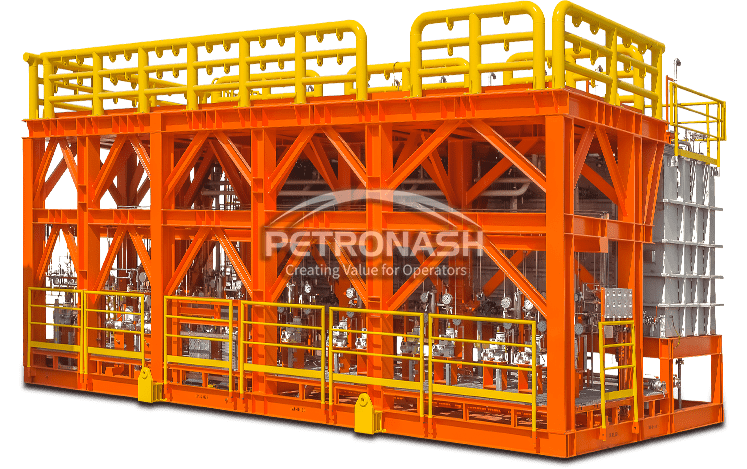

Modular Wellsite Packages

The MWP is a revolutionary turnkey solution provided by Petronash enabling the operator to adopt a standardized approach to wellsite surface

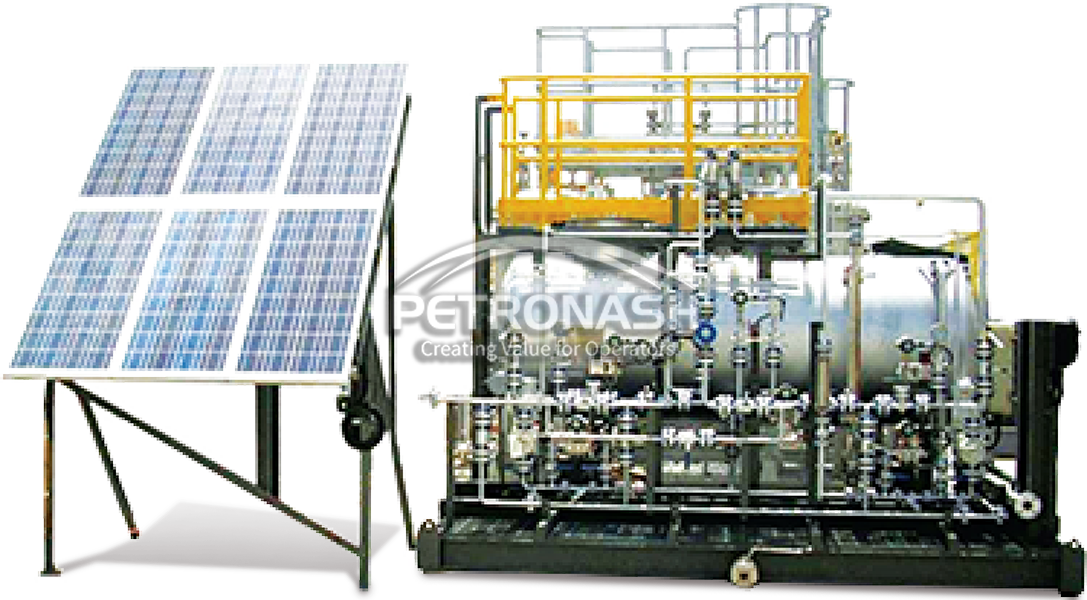

DASHPROJECTS is a pioneer with a proven track record in engineering, manufacturing and commissioning of Single-Well, Multi-Well, Integrated RTU/PLC-based, SOLAR-powered Wellhead Control

The High Integrity Protection System designed by Petronash is integrated onto the process package to prevent over-pressurization of the flow line . The HIPS will shut off the

Pressure surge can occur in Pipelines resulting in higher pressure, causing severe damages and ruptures to the installation. Events that causes pressure surge typically occurs

With the Multiport Selector Valve skids, it is possible to receive the flow from five or more oil or gas wells. It consists in one steel body with five or more incoming flow

Engineered Lube Oil system provides pressurized lubrication and protection to various types of industrial rotating equipment such as turbines, compressors, high pressure

Specializing in engineered flow solutions for process and custody transfer applications, we design, manufacture and commission complete flow metering systems for liquid and gas

Include all types of Pressure Vessels and Reactors including those with ASME “U / U2” Stamp Certification, in Horizontal / Vertical Design.

Our expertise includes :

Plasma Cutting

COLUMNS AND TOWERS (INCLUDING “U” / “U2” STAMPED VESSELS)

Include all types of Columns and Towers including those with ASME “U / U2” Stamp Certification.

We can supply the following types of Heat Exchangers in Horizontal / Vertical design :

SHELL & TUBE

COAXIAL TUBES

FLOATING HEAD TUBE SHEET

FIXED TUBE SHEETS

KETTLE TYPE RE-BOILER

U-

Our expertise include :

Shop Fabricated Tanks : All Types

Flat bottom / Sloping Bottom with Conical Roof / Flat Roof

Silos & Hoppers

Rectangular Tanks

Our scope includes :

Design

Our expertise includes :

In house semi-automatic pipe Spool Fabrication Line capable of producing 1000 Inch Dia. / Day (of average 6 Inch size)

Large Area available for storing of Raw materials

Fabrication and Assembly of all Types of Skid Packages and Modules including:

Separators Skids & other Skidded Equipment

Fuel Gas Conditioning Skids

Filtration Skids

Gas Refrigeration

As a mechanical contractor for Large Diameter Tanks our expertise includes :

Fixed Conical Roof

Fixed Aluminum Dome with Internal Floating Roof (IFR)

External Floating Roof

Our scope

Offshore Structures include:

Piles

Jackets

Decks

Flare Trestles

Bridges

Top Sides

Pipe Racks

Offshore Process Platform

Auxiliary Structures

Our scope includes :

Detailed

Design, Detailed Engineering, Procurement of Material, Fabrication, Testing, Supply of the following :

Pressure Vessels & Reactors (ASME“U & U2” Stamped)

Columns &

Design, Detailed Engineering, Procurement of Material, Fabrication, Testing, Supply of the following :

Evaporator Modules – MED / MSF

Tank Farms as per API 650 & Shop

Design, Detailed Engineering, Procurement of Material, Fabrication, Testing, Supply of the following :

Jackets & Piles

Decks

Flare Trestles

Bridges

Top Sides

Pipe Racks Modules

Process

Generally comprises of the following,

TANK PACKAGE

MECHANICAL PIPING PACKAGE

CIVIL WORKS INCLUDING MEP

ELECTRICAL PACKAGE

INSTRUMENTATION AND CONTROL PACKAGE

FIRE FIGHTING PACKAGE

HEATING

Design, Detailed Engineering Procurement of Materials, Fabrication, Supply, Erection at Site and Testing of

Large Diameter Tanks with

External Floating Roofs

Internal Floating Deck with

The Mechanical Piping work includes the following: Spool Fabrication & erection at Site, Including fabrication of Pipe Supports / Racks, erection of Pumps, Valves etc. generally for

Heavy

The civil works include the following:

Field survey.

General excavations, backfilling and site preparation works, including compaction,testing, shoring and dewatering.

Execution of all civil

The Electrical works include the followings:

Medium voltage switchgear.

Power transformers.

Emergency power switchgears.

Medium voltage distribution feeders.

400V low voltage switchboard.

The Instrumentation and Control works include the followings:

Products Distribution MOV Control System.

Fire Detection and Alarm System.

Firefighting Water and Foam Deluge Valves Control

The Firefighting works include the followings:

Firewater storage tanks

Firefighting Pumping equipment

Water distribution system

Foam distribution system

Mobile and Fixed Firefighting

The Heating System works include the followings:

Two thermal fluid boilers complete with two fuel burners (using LPG fuel for start-up and preheating and Heavy Fuel Oil for normal operation).

The Waste Water Collection System works include the followings:

HFO slop tank with external heat tracing and Insulation.

Light Products slop tank.

Slop pumps.

HFO slop piping system.

Light

The Pump Installation works include the followings:

Heavy Products Screw pumps

Light Products Centrifugal pumps

Off spec Products Centrifugal pumps

Grouting of pump pockets and base frame

The Jetty Piping works include the followings:

HFO Products pipelines with skin effect heat tracing, PUR coating and HDPE wrapping for buried piping.

HFO Products pipelines with skin effect