Asset Integrity Management Services

Asset Integrity Management Systems (AIMS) is defined as the ability of an asset to perform its necessary functions efficiently and effectively while protecting health, safety and the environment, and the means of guaranteeing that the people, processes, systems and resources that deliver integrity are in place, in use and will perform well when needed over the whole life cycle of the asset.

With almost four decades of progressive and in-depth experience in the oil and gas industry, DASH is foremost in providing fully-integrated Asset Integrity Management Services (AIMS) that are custom-tailored to ensure the safe and reliable operation of your assets.

Our prudent AIMS programs are designed to assure safety and efficiency, incorporating distinct aspects of equipment design, maintenance, inspection programs, and operational management practices.

DASH's multidisciplinary panel of safety management experts can effectively audit and optimize the existing safety configurations of your asset to ensure productivity, reliability and security.

Asset Integrity involves 4 major processes, including:

Risk Based Inspection (RBI)

Reliability Centered Maintenance (RCM)

Safety Integrity Level (SIL)

Reliability, Availability and Maintainability (RAM)

Risk Based Inspection (RBI)

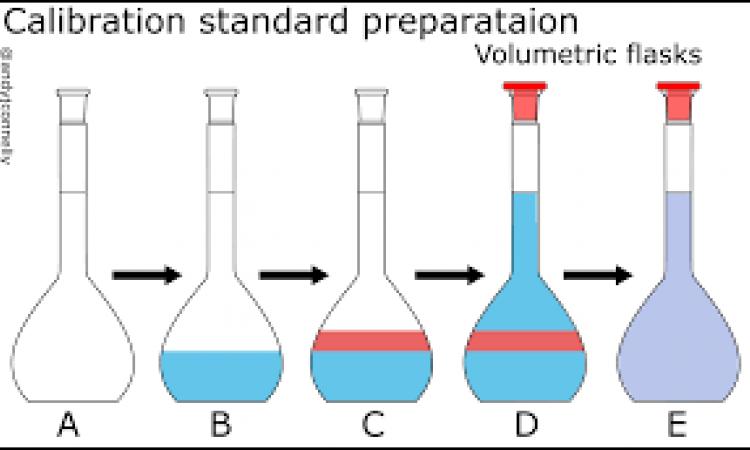

Risk-based Inspection is a type of maintenance business process used to analyze equipment, including pressure vessels, heat exchangers and piping in industrial plants. It is a decision-making technique to optimize inspection plans.

Led by industry experts, including senior consultants and engineers, DASH's unparalleled Risk-Based Inspection programs feature a total quality assurance approach, resulting in substantial cost savings for the oil and gas industry.

Reliability Centered Maintenance (RCM)

Reliability Centered Maintenance (RCM) is a unique corporate-level maintenance methodology that is executed to optimize the maintenance system of an organization or facility. Successful application of RCM can enhance reliability, cost-effectiveness, machine uptime, and a higher understanding of the level of risk that the business is managing.

At DASH, our RCM specialists apply rigorous and systematic methods in determining the appropriate maintenance tasks to address each of the identified failure modes and their consequences.

Safety Integrity Level (SIL)

Safety Integrity Level (SIL) is described as a comparative level of risk-reduction offered by a safety function, or an analysis of performance required for a Safety Instrumented Function (SIF) to maintain or achieve the safety state. In essence, Safety Integrity Level analysis is an estimation of performance recommended for a Safety Instrumented Function (SIF).

At DASH, we understand that it is crucial to perform a statistical measurement of how likely a process or a system is to be operational and ready to serve the function for which it is intended, including the calculated time to its likelihood of failure. Our uniquely designed SIL study services comply with global standards - IEC-61508, IEC-61511 and ISA TR 84.00.02 - to ensure the safe and reliable operation of the plant.

Reliability, Availability and Maintainability (RAM)

Reliability, Availability and Maintainability (RAM) are three critical system features that have considerable influence on the sustainment or total Life Cycle Costs (LCC) of an asset. The ultimate aim of a RAM study is to manage assets which run the system with minimal cost and maximum ef?ciency.

Our expert team of industry professionals provides a statistical basis for the contribution of each asset and conducts the analysis as per international standards, such as OREDA, ISO-14224, BS-5760, BS-EN 61703 and BS 4778-3.

In short, our exceptional Asset Integrity Services help our clients accomplish longer run time, reduced downtime, and enhanced mechanical integrity.

Need help or have a question?

- Risk Based Inspection

- Pipeline Inspection Management System

- Pipeline Inspection Management System (Onshore)

- Structural Integrity Management System (SIMS)

- Pressurized Equipment Management System

- Inspection Scheduling Management System (ISMS)

- Wellhead Integrity Management System (WHIMS)

- Computerized Maintenance Management System

- Asset Performance Management System

- Safety Integrity Level (SIL Study)

- Reliability Centered Maintenance (RCM)

- Reliability, Availability and Maintainability (RAM)

- Condition Based Monitoring (CBM)

- Condition Assessment Studies (CAS)

- Corrosion Management Plan (CMP)

- Corrosion Risk Assessment Study (CRAS)

- Asset Life Extension Studies

- Fitness For Service

- Close Interval Potential

- Direct Current Voltage Gradient

- ISO 55001 (Asset Management Systems)

- RBI Technical Training