Engineering Analysis

ENGINEERING ASSESSMENT, ANALYSIS & DESIGN

Dashinspectorate offers independent design verification, stress analysis, finite element analysis, remaining life assessment, re-rating, fitness for service (FFS) and adverse mechanical design options for the majority of heavy equipment found in the Oil and Gas, Power Generation and Mining industries.

oil-and-gas-fitness-for-service

We provide fitness for service assessment solutions for our clients, allowing them to reduce inspection costs and avoid or delay costly repairs whilst at the same time ensuring continued operation of critical equipment such as pipelines, pressure vessels, storage tanks, piping systems, structures etc.

Our independent engineering solutions and expert consultants provide support over all phases of the equipment life cycle from appraisal through to decommissioning.

MECHANICAL DESIGN

A robust mechanical design is the primary barrier in preventing in-service damage mechanism(s) from occurring.

Our engineering team specializes in providing expert design options where adverse operating conditions or problematic scenarios require an innovative, defensive or unique design concept. We specialize in design by analysis techniques which are engineered to fully withstand the operating environment within the Oil and Gas, Power Generation and Mining industries.

DESIGN VERIFICATION

Overlooked or incorrect design and fabrication can result in serious safety consequences in operation or become extremely expensive to reverse once equipment enters its operational life.

Our third-party design verification service ensures compliance with project requirements and international industry standards whilst also providing a barrier to eliminate errors and establish the integrity management system for the equipment.

FITNESS FOR SERVICE

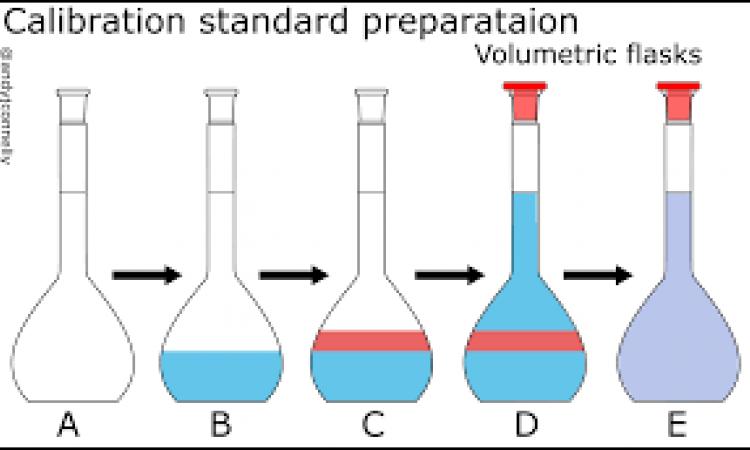

Our fitness for service and finite element analysis team have extensive experience and utilise various FFS assessment techniques to assess all types of defects and primary modes of failure including local metal loss, cracking, fatigue, pitting corrosion, creep, erosion and brittle fracture in industries such as Oil and Gas, Power Generation and Mining.

The FEA and FFS analyses we provide are practical, clearly communicated, cost effective and delivered to the highest assessment procedure standards known in the Oil and Gas, Power Generation and Mining industries. The output of our FFS and FEA assessments allows our clients to make appropriate decisions regarding fitness for service evaluation including running as-is, retiring, re-rating or altering equipment prior to operation. We not only provide quantitative engineering evaluations but assist in defining the risk and consequence of all possible scenarios, allowing the most appropriate options to be understood and implemented.

Need help or have a question?

- Risk Based Inspection

- Pipeline Inspection Management System

- Pipeline Inspection Management System (Onshore)

- Structural Integrity Management System (SIMS)

- Pressurized Equipment Management System

- Inspection Scheduling Management System (ISMS)

- Wellhead Integrity Management System (WHIMS)

- Computerized Maintenance Management System

- Asset Performance Management System

- Safety Integrity Level (SIL Study)

- Reliability Centered Maintenance (RCM)

- Reliability, Availability and Maintainability (RAM)

- Condition Based Monitoring (CBM)

- Condition Assessment Studies (CAS)

- Corrosion Management Plan (CMP)

- Corrosion Risk Assessment Study (CRAS)

- Asset Life Extension Studies

- Fitness For Service

- Close Interval Potential

- Direct Current Voltage Gradient

- ISO 55001 (Asset Management Systems)

- RBI Technical Training