In-Service Inspection

Dashinspectorate ’s certified inspectors are available to support your requirements in in-service tank inspection, in-service inspection of pressure vessels, piping in-service inspection.

Above Ground Storage Tank Inspection (API 653)

In-Service & Out-of-Service Inspections (Internal & External).

Consultancy for Maintenance & Repair works.

Fitness for service evaluation .

Failure analysis & investigation.

Integrity Analysis, Remaining life Assessment and Corrosion Rate Evaluation.

Damage Mechanism Analysis (API 571).

New tank fabrication inspection/ Reconstruction

Tank settlement evaluation (Foundation, Shell, Bottom & Edge Settlement).

Dimensional survey (Roundness, Plumbness, Peaking & Banding measurements).

Coating/ Painting/ Lining inspection.

NDT- MFL (3D floor map), Vacuum box, UT, MT, PT, AUT (Scorpion) B Scan, Hand Scan, RT, PAUT, SRUT etc..

Mechanical/ Metallurgical tests and PWHT.

Corrosion Monitoring.

Thickness Monitoring Service(TML’s).

Hydro test & Pneumatic Test .

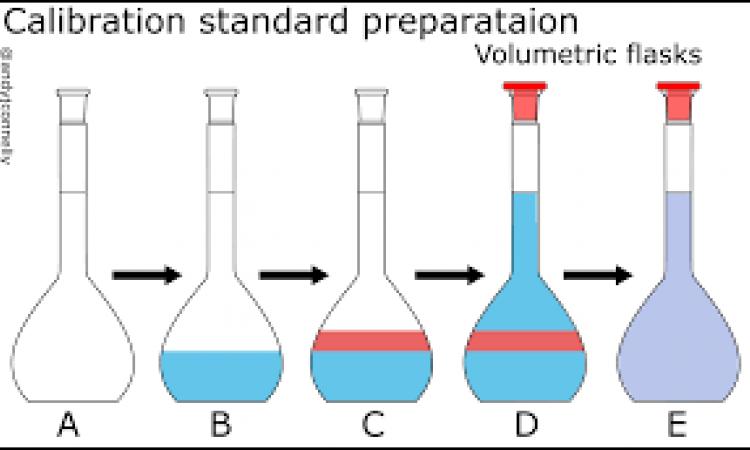

Tank Calibration .

Pressure Vessel Inspection (API 510)

Detailed Internal and external inspection (during On-steam/ Off stream and Turnaround)

Consultancy for Maintenance & Repair works.

Fitness for service evaluation .

Failure analysis & investigation.

Integrity Analysis, Remaining life Assessment and Corrosion Rate Evaluation

Damage Mechanism Analysis (API 571)

On-site fabrication / erection/ installation inspection

Vendor Surveillance and Audit Services

NDT – UT, PAUT, MT,WFMPI, PT, LT, RT, LRUT, SRUT, IRIS

Corrosion Monitoring

Corrosion Monitoring

Thickness Monitoring Service(TML’s)

Rerating

Mechanical/ Metallurgical tests and PWHT

Hydro test & Pneumatic Test

Piping Inspection (API 570):

Turnaround/ On-stream Inspections

External Visual Inspection of Above Ground Pipelines

Consultancy for Maintenance & Repair works

Fitness for service evaluation

Failure analysis & investigation

Integrity Analysis, Remaining life Assessment and Corrosion Rate Evaluation

Damage Mechanism Analysis (API 571)

NDT – UT, PAUT, MT, PT, LT, RT, MFL, LRUT, SRUT, IRIS

Corrosion Monitoring

Thickness Monitoring Service(TML’s)

Mechanical/ Metallurgical tests and PWHT

Hydro test & Pneumatic Test

Volumetric Calibration

Need help or have a question?

- Risk Based Inspection

- Pipeline Inspection Management System

- Pipeline Inspection Management System (Onshore)

- Structural Integrity Management System (SIMS)

- Pressurized Equipment Management System

- Inspection Scheduling Management System (ISMS)

- Wellhead Integrity Management System (WHIMS)

- Computerized Maintenance Management System

- Asset Performance Management System

- Safety Integrity Level (SIL Study)

- Reliability Centered Maintenance (RCM)

- Reliability, Availability and Maintainability (RAM)

- Condition Based Monitoring (CBM)

- Condition Assessment Studies (CAS)

- Corrosion Management Plan (CMP)

- Corrosion Risk Assessment Study (CRAS)

- Asset Life Extension Studies

- Fitness For Service

- Close Interval Potential

- Direct Current Voltage Gradient

- ISO 55001 (Asset Management Systems)

- RBI Technical Training