In Service Management

IN-SERVICE INTEGRITY AND INSPECTION MANAGEMENT

Integrity and inspection management services provided by an independent third party is a widely used strategy in the western world and demonstrates responsible operations. It has a positive effect on service quality, ensures safe operation and helps to reduce facility’s insurance premiums.

in service inspection

Dashinspectorate provides multidisciplinary teams to manage and implement integrity and inspection services on behalf of our clients over a range of geographical locations such as:

Algeria

Egypt

Iraq

Kurdistan

Oman

Qatar

Saudi Arabia

South East Asia

United Arab Emirates (UAE)

Headquartered in the UAE, our asset integrity management services cover all operational requirements from corrosion and cathodic protection management through to in-service inspection, fitness for service assessment, remaining life assessment, condition assessment, KPI reporting, external integrity audit and failure/incident investigation. Our services cover a range of assets including, but not limited to, pressure systems, structures, storage tanks & pipelines.

Our operational integrity teams based across the MENA region have a combined range of skills and knowledge and are well-versed with the region’s regulatory requirements which provide a comprehensive and educated third-party service for our clients’ operations.

Our qualified inspection engineers and technicians are experienced across various industries such as Oil and Gas, Power Generation and Mining. All personnel follow our in-service inspection standard and testing procedure(s) with work flow performed in accordance with our established integrity management process.

Our clients can rest assured that the integrity of their facilities is managed by an independent team of specialists who bring failure knowledge, experience and technology from other operating facilities in the region and are not biased by operational or commercial pressures.

Need help or have a question?

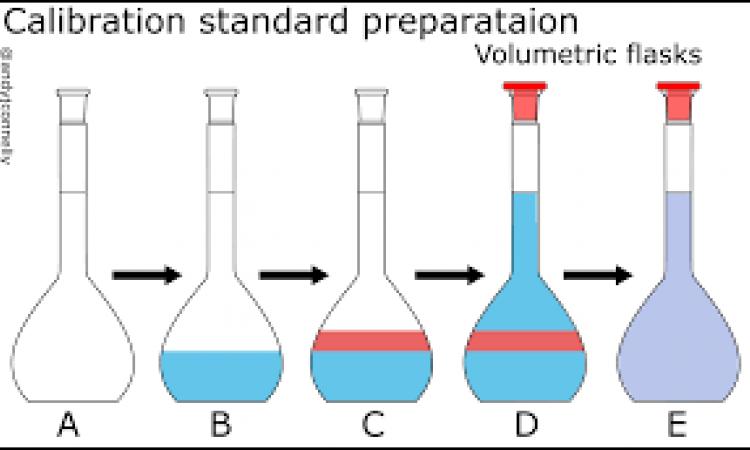

- Risk Based Inspection

- Pipeline Inspection Management System

- Pipeline Inspection Management System (Onshore)

- Structural Integrity Management System (SIMS)

- Pressurized Equipment Management System

- Inspection Scheduling Management System (ISMS)

- Wellhead Integrity Management System (WHIMS)

- Computerized Maintenance Management System

- Asset Performance Management System

- Safety Integrity Level (SIL Study)

- Reliability Centered Maintenance (RCM)

- Reliability, Availability and Maintainability (RAM)

- Condition Based Monitoring (CBM)

- Condition Assessment Studies (CAS)

- Corrosion Management Plan (CMP)

- Corrosion Risk Assessment Study (CRAS)

- Asset Life Extension Studies

- Fitness For Service

- Close Interval Potential

- Direct Current Voltage Gradient

- ISO 55001 (Asset Management Systems)

- RBI Technical Training