Construction Services - Tankage

DASHPROJECTS ("DASH"), a subsidiary of DASH Group of Companies, is well established as a tank construction company to offer a wide range of capabilities in construction, erection & maintenance of tanks for the Oil & Gas, Petroleum, Petrochemical & Pharmaceutical industries.

Our storage solutions for the upstream & downstream oil & gas markets extend to all types of tanks including atmospheric tanks, spherical tanks, double-walled tanks, bulk liquid terminals, low temperature & cryogenic systems, horizontal vessels ("bullets"), cone roof/dome roof/floating roof tanks.

We specialise in API 650 & API 620 standards. We know precisely what it takes when it comes to designing and construction of tanks for bulk liquid storage. We are able to provide the full service of tank construction at field as well as the service of pre-fabrication of tank plates, spiral staircases, tank bridges, accessories & appurtenances. On top of that, we can provide the design with strength calculation with the generation of tank construction drawing.

DASH has a long history of providing multi-disciplinary, turnkey EPCM solutions in the fields of bulk liquid storage terminals, tank farms, offsite and utilities for refineries and petrochemical plants. In short, we know precisely what it takes when it comes to designing and constructing tanks for bulk liquid storage.

Being an one-stop service provider, we are able to generate the seamless process that connects every single steps from engineering, procurement, fabrication, logistic to tank construction. We provide comprehensive tank design with strength calculation together with detailed tank construction drawings.

Our services include:

Tank Fabrication Works

Cutting, beveling & rolling of tank plates, fabrication & installation of tank outfittings such as tank nozzles, gauge pole, tank bridge, manholes, tank platform, floating roofs, spiral stairway and ladder. We are also capable and experienced to do fully shop fabrication and assembly works for atmospheric tanks.

Tank Construction Works

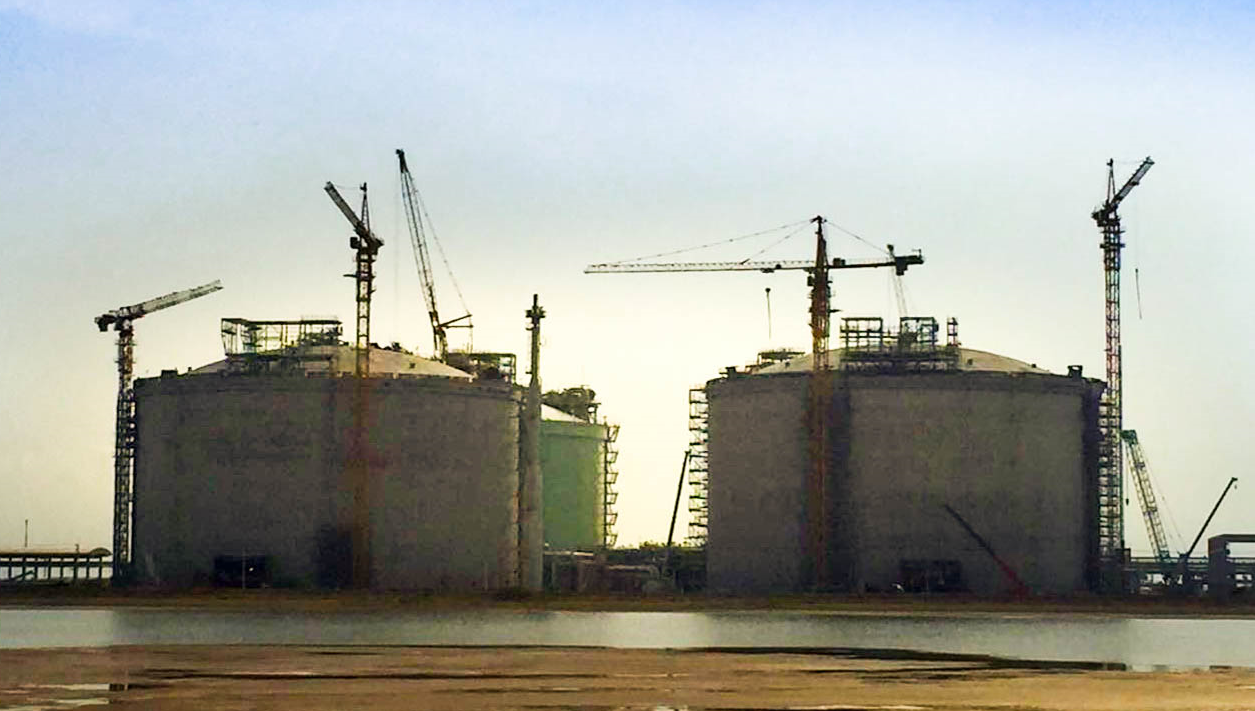

Construction of all types of tanks including spherical tanks, double-walled tanks (for low temperature storage such as LNG), bullet tanks, vessels & atmospheric tanks (for cone roof/dome roof/floating roof tanks) for terminals, tank farms for refineries & petrochemical plants

Occupying a combined total area of more than 30 hectares, these 6 workshops are capable of fabricating more than 1.2 million DB of piping, 9,000 tonnes of structural steel, and 42,000 tonnes of plates rolling per year.

Over the past many years of experience, we have been constantly developing and implementing innovative ways including mechanization in our tank fabrication and construction processes, as part of our continual efforts in achieving safety, quality & productivity ("SQP") excellence for all our projects deliveries.

Automation on Welding:

Striving to be time & cost effective in our construction processes, DASH utilizes mechanization and automation to enhance the work productivity. Examples are the usage of auto vertical welding machine and auto girth welding machine in our work areas, which not only shorten the turn-around time for each job but also improve on the quality of work.

With our continuous drive towards technological improvements, we have also successfully implemented the auto cutting machine for thicker plates (up to 80mm) and the two-side cutting system in our recent projects.

Sheltered Gantry Crane for Tank Farm Construction:

As a record made, DASH is the first tank builder in Singapore to construct tanks using the sheltered gantry crane (46 nos of tanks at TOTAL Lube Oil Blending Plant). The gantry crane is designed with a built-in shelter, we are literally bringing our workshops to the field when we could allowed work to continue undisrupted even under bad weather conditions. Span at 50m with width 30m, this sheltered gantry crane aims to reduce congestion possibly caused by the footprints of multiple mobile cranes, at the same time incorporating wind speed control & movement sensor alarm. Safety level of work can be enhanced by not allowing crisscrossing of cranes and reduced instances of suspended load as the machine is able to lower the load to waist level. Productivity is also increased with the shorter construction time as a result of greater work efficiency.

Tank Jacking System:

We can provide both conventional method and jacking system method for field erection of tank. The jacking system is the preferred and safer method for construction & installation of tanks whereby accesses and/or working spaces is a concern. We implement the tank jacking as this assembly method is stable, reliable, fast-progress & safe. This method eliminate the usage of crane & reducing risk of working at height & possible injuries. Various type of tank designs could be built by tank jacking method even including the erection of cone roof with columns. In short, jacking method not only ensure the quality of work & saving labor head count which equates to a saving in project costs as well as significantly reduces the chance of accident due to working at height.

Roof Lifting by "Bazooka" Method:

After completion of the erection of tank shell, a series of specially designed grip hoists ("Bazooka") will be installed around the tank circumference above the top angle for the purpose of lifting of the roof. Primary advantage of these Bazooka is that there are equipped with pneumatically operated actuator for synchronized movement to keep the slings in equal tension at all times. Engineering calculation will be conducted prior to the lifting to determine the total number of Bazooka required to ensure safe lifting operation. The advantages of this method is not only safer, it eliminates the usage of large cranes and lesser manpower required. On top of that, it gives precision fitting of the roof - this reduces the chances of misalignment.