STEEL DECKING

EBS also offers steel deck for steel buildings or mezzanines to suit structural specifications. There are two profiles available in EBS production line; they are EBS50X225 and EBS75X300 with covering width of 900mm.

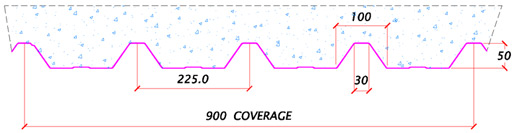

Low trough decking panel EBS 50X225

Thickness : 0.43 mm and 0.60 mm

Coating : Mill finish

Material Specification : Aluzinc sheeting (ASTM A792M GR.50) Galvanized sheeting (ASTM A653 GR.50)

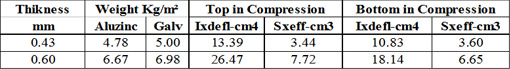

Section Properties per meter width

Calculations are based on a minimum yield stress of 345 N/mm² (50 KSI)

Thickness refers to metal core (Base Metal Thickness BMT)

Allowable Load (KN/m²)

Note:

The allowable loads are due to bending strength or deflection limited of span/200.

All stated allowable loads are to include SWT of decking and concrete.

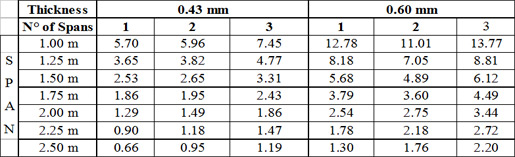

High trough decking panel EBS 75X300

Thickness : 0.80 mm and 1.0 mm and 1.2 mm

Coating : Mill finish

Material Specification : Galvanization to G90 (ASTM A653M-95) Steel Grade SQ-50 (ASTM A653M-95)

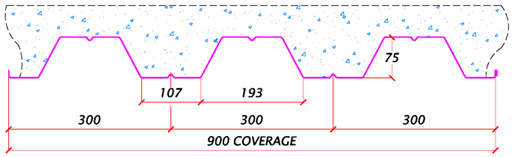

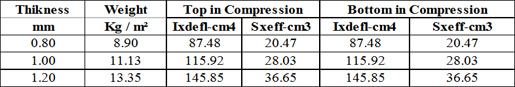

Section Properties per meter width

Calculations are based on a minimum yield stress of 345 N/mm² (50 KSI)

Thickness refers to metal core (Base Metal Thickness BMT)

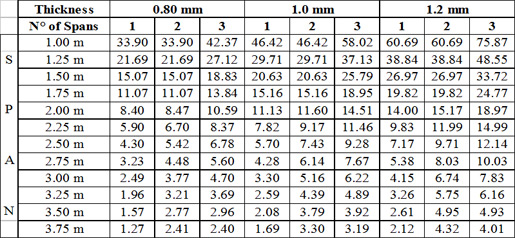

Allowable Load (KN/m²)

Note:

The allowable loads are due to bending strength or deflection limited of span/200.

All stated allowable loads are to include SWT of decking and concrete.

SPECIFICATIONS

Design Codes

Hot-rolled structural steel is designed in accordance with AISC or British standard BS 5950.

Built-up frames and other welded members are designed in accordance with the American Institute of Steel Construction AISC “specification for Design, Fabrication and erection of structural Steel Buildings.

All welding conform to the requirements of American Welding Society.

Light Gauge Cold-formed members are designed in accordance with the requirements of the American iron and Steel Institute “Specifications of the Design of Light Gauge Cold-Formed Steel Structural Members”.

Design Loads

Structures are designed to withstand the dead load and:

- Live Load

- Prescribed wind load

- Collateral Load and

- Equipment Loads

The design procedures follow the Metal Building Manufacturer’s Association “Low Rise Building Systems Manual”.

Material Specification

Hot rolled sections are fabricated from material having a minimum yield stress of 345 N/mm2 (50 ksi) conforming to ASTM A-572 or minimum yield 275N/mm2 conforming to EN10025 S 275.

Flange and Web material for built-up sections, connection plates and stiffeners are fabricated from material having a minimum yield stress of 345 N/mm2 (50ksi) conforming to ASTM A572 Grade 50.

All galvanized light gauge cold-formed structural members are fabricated from steel coil having minimum yield stress of 365 N/mm2 with a galvanized coating of 275 g/m2 conforming to JIS G3302 SGH490.

Aluminum Zinc coated steel and pre-painted Galvanized coated steel sheeting, eave Gutter, downspout, Flashing and Trims have a minimum yield strength of 345 N/mm2 (50ksi) with approximately 55% aluminum and 45% zinc alloy coating of 150g/m2 (total on both sides), conforming to ASTM A-792 Grade -50B.

Galvanized coated steel and pre-painted Galvanized coated steel sheeting, Eave Gutter, Downspout, Flashing and trims have a minimum yield strength of 345 N/mm2 (50ksi) with a ‘galvanized coating’ of 275 g/m2 conforming to ASTM A-653 Grade-50.

Aluminum and pre-painted Aluminum Sheeting, Eave Gutter, Downspout, Flashing and Trims have minimum yield strength of 180 N/mm2 (30ksi) conforming to Aa-3105-H16.

High tensile bolts conform to the requirements of ASTM A-325.

Diagonal brace rods and anchor bolts have minimum yield strength of 345 N/mm2 (50ksi) conforming to ASTM A-572 Grade-50.