INTEGRATED MAINTENANCE

DASH PROJECTS, a subsidiary of the DASH Group of Companies, is well established as an Integrated Maintenance Company offering a wide range of capabilities in maintenance & pre-commissioning services for the Oil & Gas, Petroleum, Petrochemical & Pharmaceutical industries.

Today, we have established an effective and a highly accessible maintenance infrastructure on Jurong Island. It supports an environment where the nature of the operation demands the utmost of resource availability, logistical support, engineering and supply, all within a one-stop shop. We provide a complete range of industrial services. This includes the ability to provide services for small capital projects and plant engineering for ongoing maintenance routines.

Providing high quality & responsive maintenance, and EPC services for our customers, our services yield significant benefits such as lowered operational costs, improved deployment time and with resource optimization. Our strategies for one-stop integration are to fully understand our client’s needs in overall, before to plan, design and integrate diverse components for our clients directly through all shared services. We have a pool of expertise with proven track record in delivering complex solutions and effective and quick execution with diverse technical know-how.

Within a short span of operation since year 2001, DASH has to-date established working relationship with a list of world renowned customers.

DASH has established itself as a market leader in integrated maintenance services and has a dominant presence within the chemical hub IN MENA REGION

We have a total workforce of over 800, including over 600 multi-skilled craftsmen.

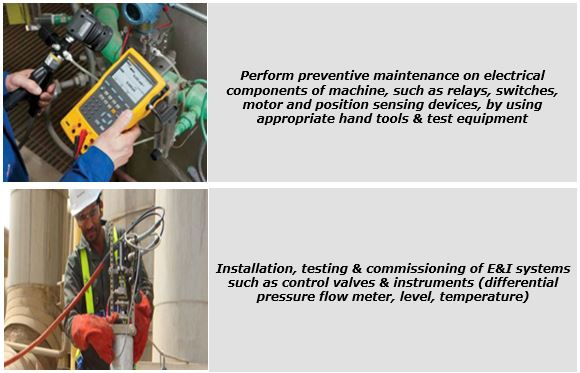

Our services include:

- Daily Maintenance

- Operation Support

- Planned Periodic Maintenance

- Shutdown / Turnaround Maintenance

- Plant Startup Commissioning Support

- Warranty Maintenance

- Condition Monitoring/ Reliability Engineering

- Performance Enhancement Plant Modification project

- Computerized Maintenance Management System (CMMS)

Our value-addedness are incorporating the best practices developed in many industries. Work processes are driven towards a more predictive environment with safety-conscious, multi-skilled workforce.

DASH has a total of 5 fabrication workshops spanning across key regions in the Middle East and Southeast Asia, strategically align with our group’s direction for the support of our multinational projects with our unique execution plans. Apart from providing fabrication support to our EPCM services in these regions, our workshops are fully equipped with capabilities to support fabrication projects as required by our clients worldwide.

Occupying a combined total area of more than 30 hectares, these 5 workshops are capable of fabricating more than 1.2 million DB of piping, 8,000 tonnes of structural steel, and 45,000 tonnes of plates rolling per year. With our effort in expanding our presence in the Middle East, we are expecting our 6th workshop to be completed in Fujairah, UAE by Q3 2017.

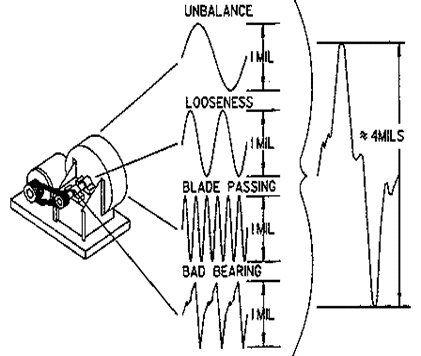

Vibration Monitoring and Implementation

A predictive technique of regularly monitoring selected parameters (typically vibration) of rotating equipment to identify early onset of machinery problems.

Benefits:

- Results in fewer unexpected failures

- Optimises resources and manpower

- Increased productivity

- Improved product quality

- Reduced maintenance costs

Machinery Diagnostics

In depth diagnostics of machinery problems due to resonance, misalignment, imbalance, looseness, bearing & gear faults, etc. It is applicable to most types of rotating machinery.

Benefits:

- Increase machine uptime and operational life

- Detect potential failures

- Reduce maintenance cost and hence increase plant efficiency

- Improve safety environment

Dynamic Balancing

On-site 1 or 2 Plane Dynamic Balancing can be performed for motors, fans, propellers, turbines and most other rotating machinery.

Benefits:

- No dismantling required hence time & labour cost minimize

- Increase machine life span and availability

- Prevent damage due to dismantling and transportation

- Improve safety environment

Oil Analysis

Assessment of oil degradation & contamination for the evaluation of machine being lubricated. Analysis testing performed locally or via a third party certified lubrication testing laboratory.

Benefits:

- Enables the proactive control that lead to lubricant & machine failure

- Identifies components which are at the onset of the severe wear stage

- Ideal as a complementary technique to vibration or infrared thermography

- Minimises the cost of laboratory analyses by scheduling on condition only, or less frequently for lubricant checks

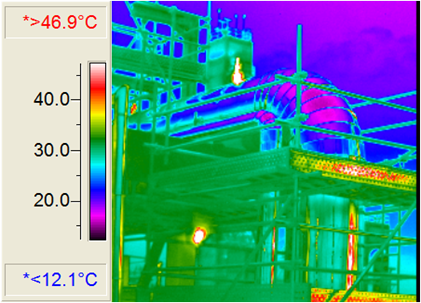

Infrared Thermography (IRT) Survey

Infrared Thermography can be used to identify any problem that is associated with a change in temperature that is out of the ordinary. IRT helps to pinpoint failures in electrical, mechanical & process related areas.

Benefits:

- Provides non-intrusive instantaneous inspection

- Detect potential failures & hazards

- Provides a complementary inspection method for the diagnosis of plant equipment, performance monitoring & safety evaluations