FABRICATION SERVICES

DASHPROJECTS has a total of 6 fabrication workshops spanning across key regions in Middle East and Southeast Asia. Apart from providing shop fabrication support to our EPCM services, the workshops also undertake standalone fabrication projects for various multinational and local clients.

The 6 workshops occupy a combined total of more than 30 hectares, capable of more than 1.2 million dB of piping, 9,000 tonnes of structural steel, 42,000 tonnes of tankage works per year.

One-stop solution is provided to satisfy all your requirements. Our main core specializations are:

- Tankage pre-fabrication

- Structure fabrication

- Piping fabrication

- Pressure vessel fabrication

SS, CS, AS and all metals are designed, purchased and fabricated in accordance with international standards such as ASME, TEMA, ASTM, API, NACE etc.

Instead of outsourcing, we prefer to keep all ancillary activities in-house in view to upkeep the highest standards and efficiency we have always maintained. Within the confines of our workshops, we have our own blasting, painting, NDT, inspection yards that complement our core services.

Logistics and Materials Management

Logistics and materials management can be a headache in a workshop, especially for bigger-sized jobs.

To ensure full accountability and tracking, each of our workshop is equipped with the most advanced software and equipment for tracking of raw materials and finished products - and we are always happy to integrate such system to that of our clients. Software we currently use:

- SmartPlant Systems

- WIMS (Weld Inspection Management System)

- FACTS Integrated Business Management Software

- Barcoding System

Our Services – Piping

We have more than 30 years of experience in piping fabrication and have served a wide range of clients across Asia and Middle East which include Exxon Mobil, Chevron, PetroChina, Evonik etc.

We have the capability of handing fabrication project ranging from a few thousands dB to up to a million dB. From pipes as small as ½ an inch to 40 inch, from stainless steel to alloy steel, from cutting to painting and blasting - we have the foundation firmly planted in each area.

We are also able to spearhead production planning. With your ISO diagram, our team of highly-skilled engineers will work on required spool generation, while always keeping in mind your construction and operational requirements, thus ensuring quality outputs are always delivered on time.

Our full suites of services have been designed to give you a peace of mind when you choose us to be your partner.

Our Services – Steel Structure

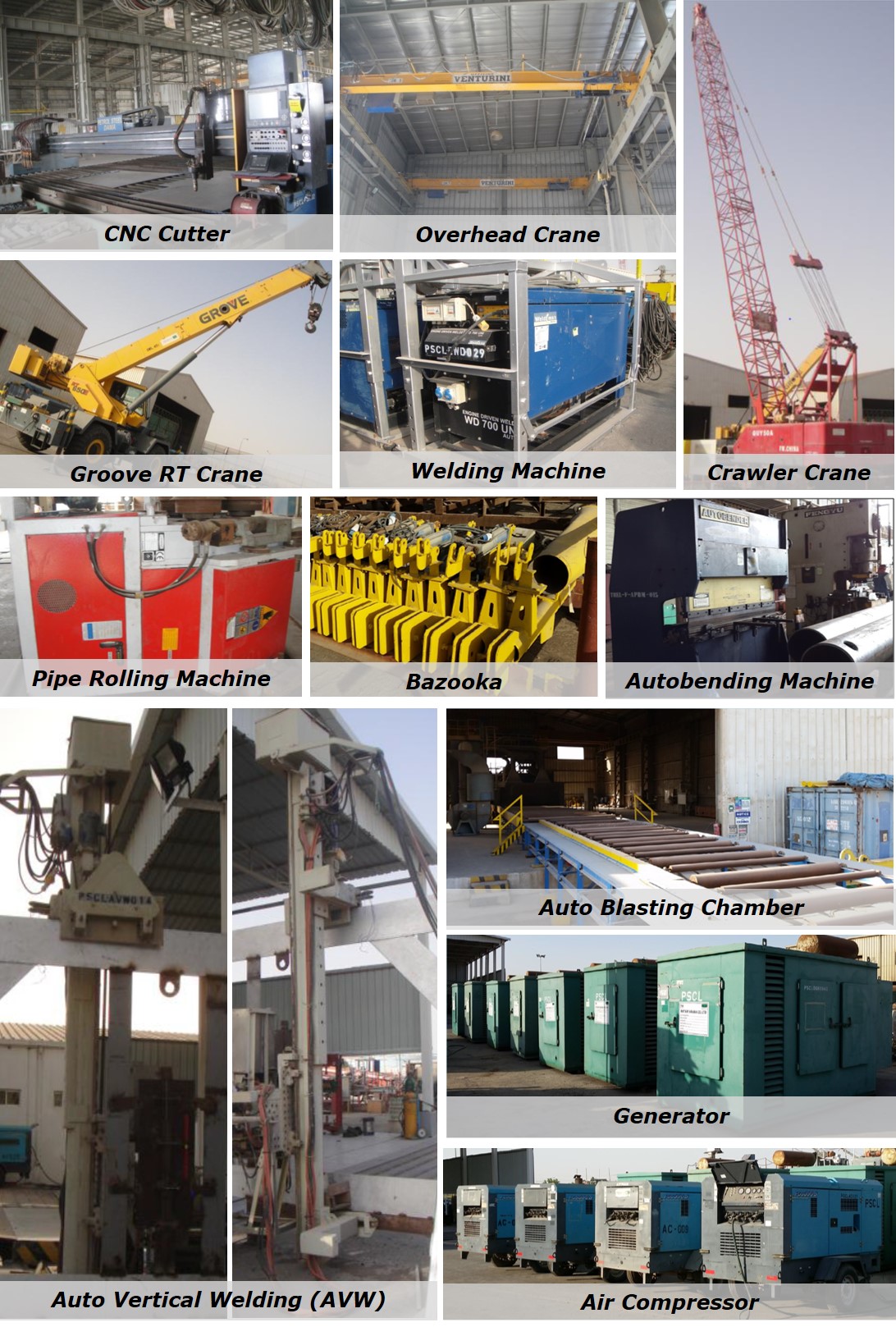

Fabrication of structures in workshop is one of the obvious ways to saving time and money. Our workshops are equipped with an array of fabrication machineries and equipment that will suit your project requirements. Each of our workshop is equipped with CNC cutters, overhead cranes, welding equipment/benches, rolling machines etc. that will allow for swift and precise execution of each fabrication project.

We are also a specialist in modularized units that can help to save you precious time especially during compressed onsite schedule. Our team has extensive experience in the fabrication of modular units such as pipe structures, substations, buildings, walkways etc. We trust that you will meet the tightest of deadlines with our expertise.

Our Services – Tankage

Tanks are the heart and soul of each terminal which explains our profound expertise in this area as well.

Our shops are equipped with plate rolling machines, CNC cutters, AVW & AGW to size and shape plates as per your project requirements. We are also able to execute fabrication for different types of materials which include cryogenic, spherical, pressure vessel tanks etc.

When required, we will be able to fabricate and assemble smaller-sized tanks in the workshops, before transferring them to the worksite that will allow for swift ground installation.

Our Services – Pressure Vessel

We have decades of experience in shop fabrication of pressure vessels and have established a huge base of international clientele which includes companies like Saudi Aramco, Total, Oiltanking just to name a few.

We have completed numerous pressure vessel fabrication projects across South East Asia and Middle East, and currently boosts to have built the largest bullet tank in the history of oil refinery. Each of the bullet is 84m long, with a diameter of 9m, and weighs close to 1,300 tonnes!

Equipment List

Equipment costs are often one major component of projects. In DASHPROJECTS, we have invested in a wide range of equipment that are ready to be mobilized for projects both in shop and on site. The usage of these equipment allows us to pass on cost savings to our customers over time.

Other than cost savings, having such equipment drives productivity and quality, ensuring our clients are always kept happy with our delivery. Selected equipment we have in our inventory:

- AGW & AVW

- Self propelled mechanised submerged Arc DC wire feeder

- Auto pipe fabricators

- Auto blasting machines

- Plate rollers up to 90mm thick

- Hydraulic press

- CNC cutting machines

- Shelter gantry cranes (50m span)

- Crawler/RT/Tower/Overhead cranes

- Truck and trailers