INTEGRATED WELL INTERVENTIONS

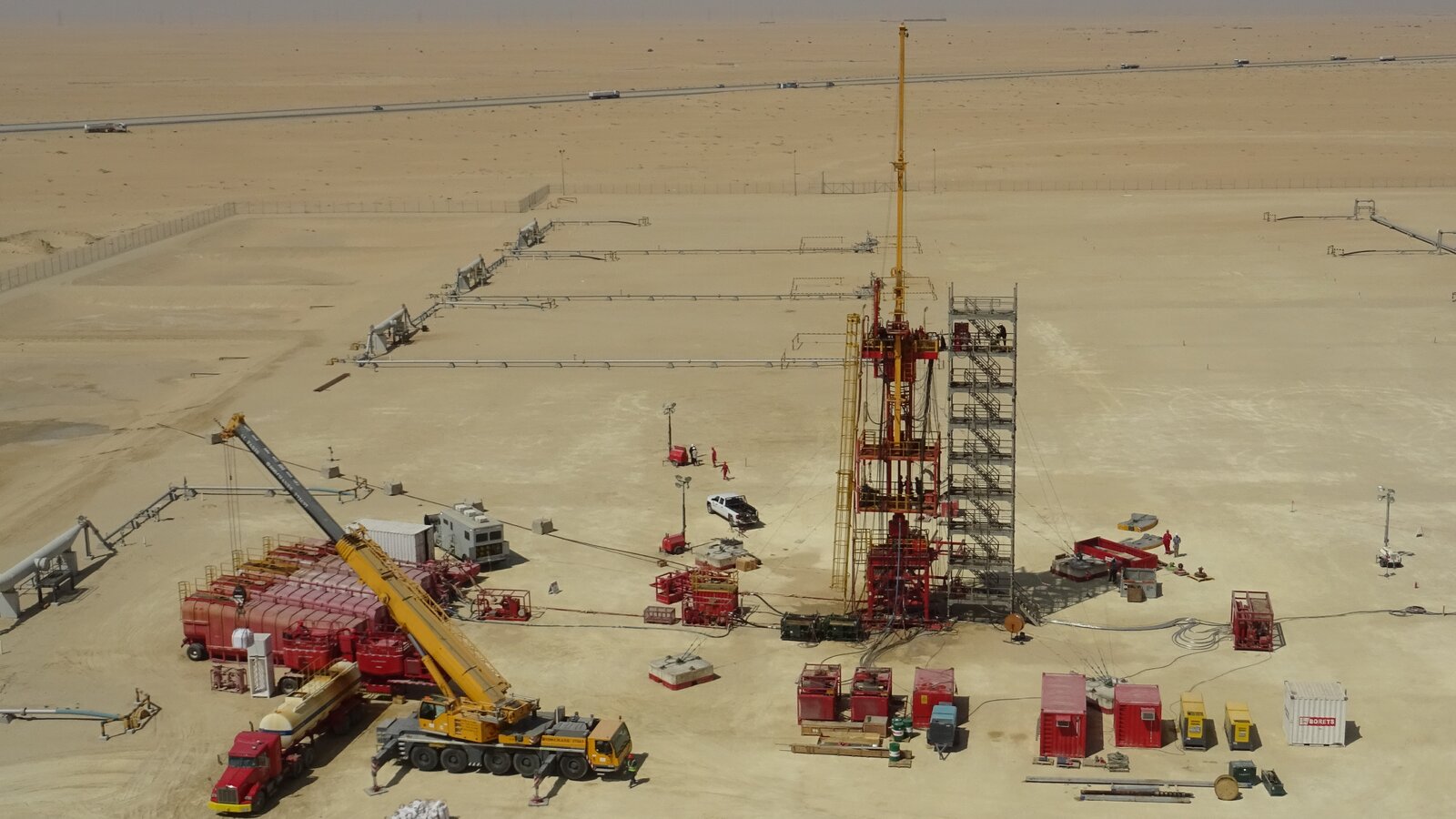

Intervention expertise to maximize asset value

Value-driven performance, superior execution.

Halliburton delivers integrated well intervention through proprietary workflows, upfront planning, and single-point accountability.

Halliburton capabilities and track record cover the full spectrum of interventions including scale, sand removal, water shut-off, recompletions, artificial lift, and stimulation.

Project Execution teams leverage processes and procedures led by experienced Project Managers that are supported by real time operations capabilities. Cross-trained personnel and experienced well site supervisors reduce personnel and increase capabilities on location.

Conveyance

Aligning the method of conveyance to objectives and location of the well is critical to complete solution and value for the intervention project.

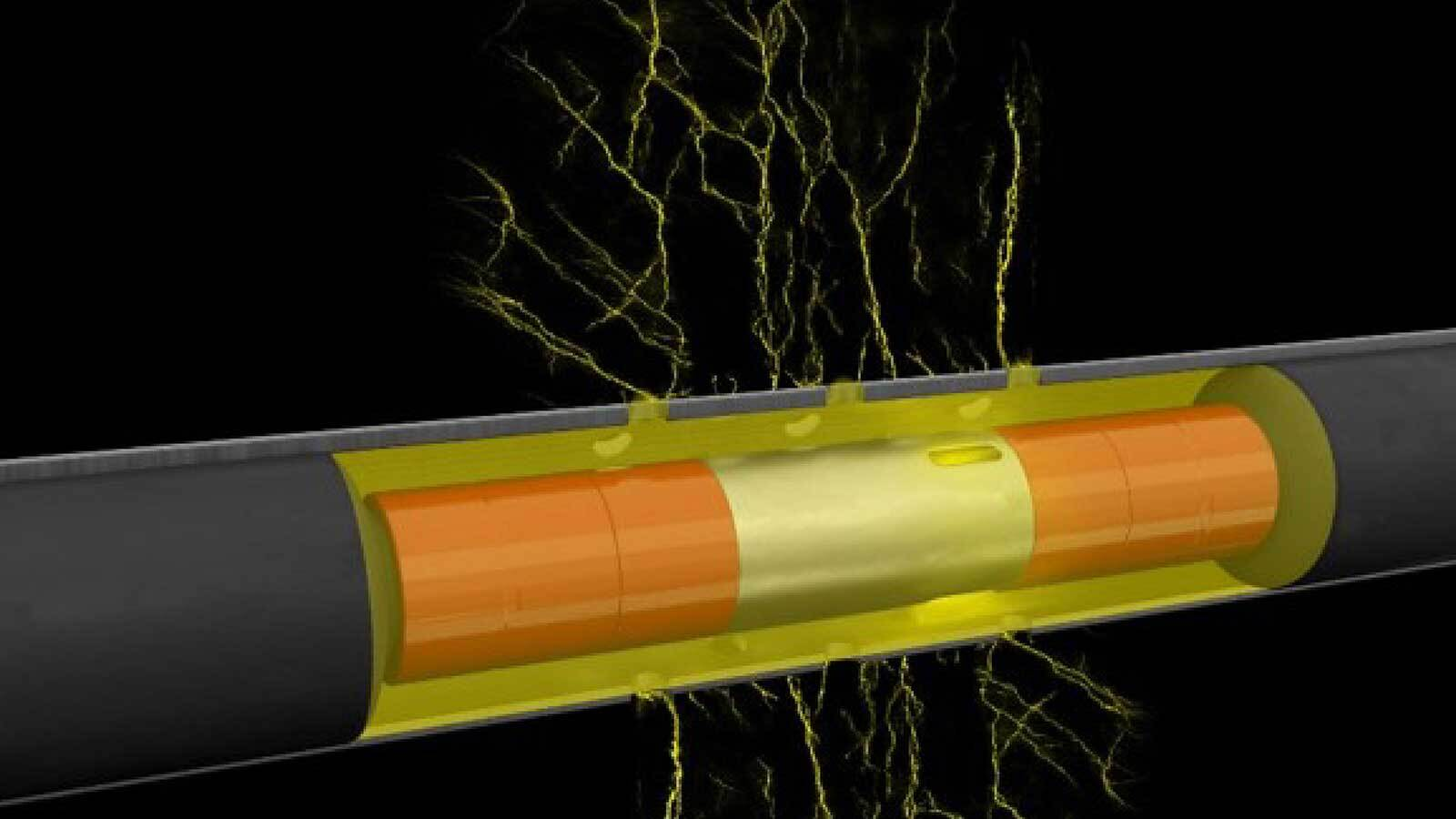

RELAY™ Digital Slickline improves intervention efficiency

With the RELAY digital slickline system, you can improve well intervention efficiency, reduce uncertainty, and minimize environmental impact.

Coiled Tubing Equipment and Services

Coiled tubing solutions offer the latest safety features and technologies to optimize operational efficiency and service reliability.

Hydraulic Workover and Snubbing

Halliburton HWO units are the ideal well intervention solution for well maintenance, live well interventions, and re-entry operations.

Well Remediation

Develop and deliver tailored solutions specific to each well to remediate and restore production.

EquiSeal™ Conformance Service

EquiSeal conformance sealant is a game changer in the treatment of horizontal wells or highly deviated wellbores.

SPECTRUM® e-IP

SPECTRUM e-IP is an inflatable isolation tool equipped with a unique electric actuation system that delivers unmatched treatment precision.

Pulsonix® TFA Service

Halliburton Pulsonix Tuned Frequency Amplitude Service is an innovative tool that helps optimize near-wellbore treatment effectiveness.

Recompletions and Stimulations

Integrated solutions to evaluate, optimize, redesign, recomplete, restore and improve productivity of your wells.

PinPoint Stimulation Technology for Unique Challenges

PinPoint solutions deliver the optimum treatment of multi-stage fracturing and can be deployed with coiled tubing or hydraulic workover units.

Hydra-Jet™ TS

Hydra-Jet TS is an abrasive perforating took that uses jet orifices to focus a fluid slurry into a flow stream.

X-Tend™ Acid Stimulation Service

A low viscosity, retarded acid for deep penetration into the formation.