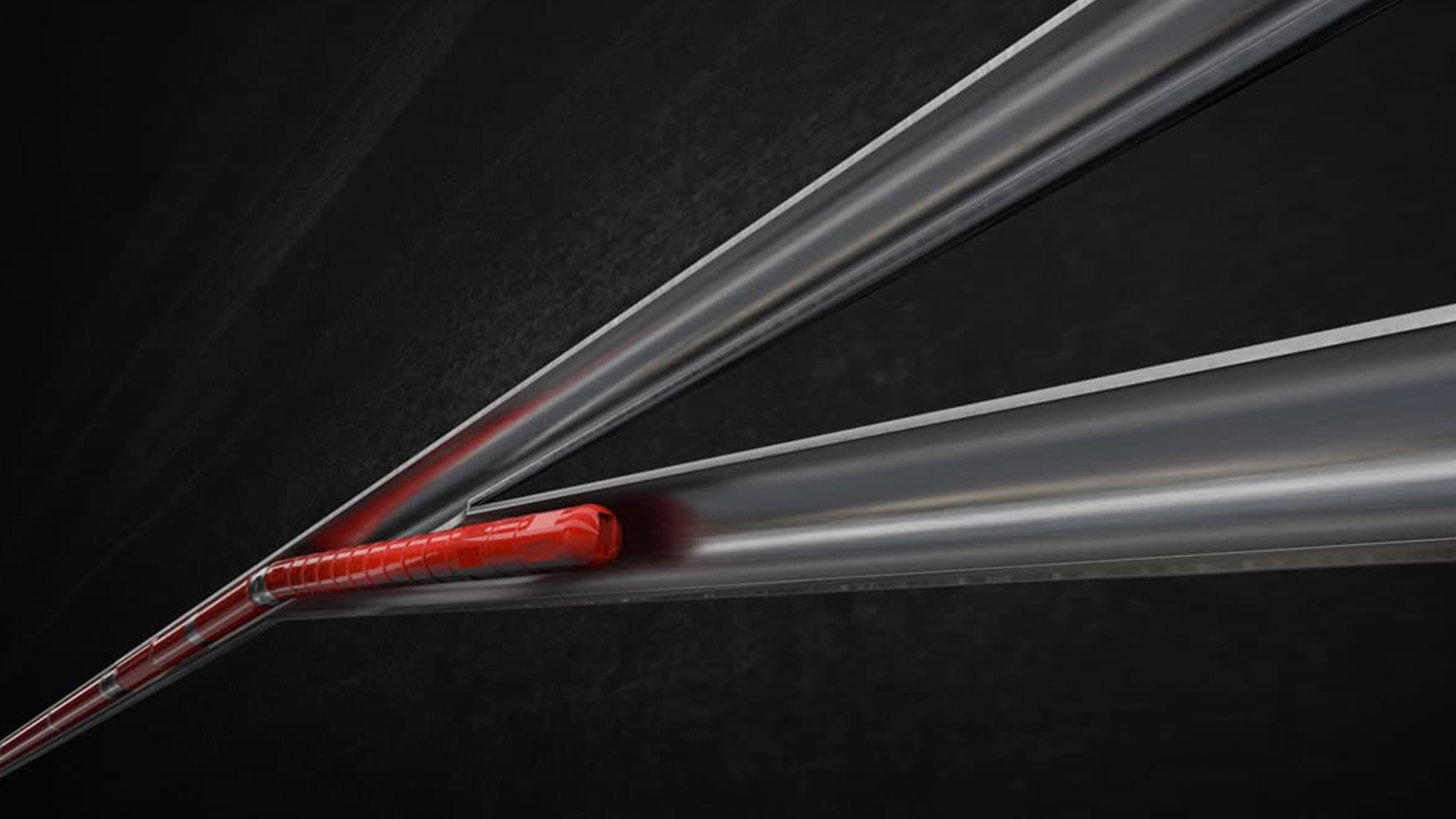

well-intervention-and-diagnostics - coiled-tubing

Coiled tubing equipment for well intervention

Coiled tubing is one of the most widely used tools in the well intervention sphere, with applications in all areas of the well life cycle.

TALK TO AN EXPERTTop technical experts and state-of-the-art technology

Halliburton has the right coiled tubing equipment to solve well intervention challenges, with applications in all areas of the well life cycle, including:

- Stimulation through acidizing or hydraulic fracturing

- Completion with plug millout in unconventional wells

- Well integrity remediation by mechanical or chemical means

- Flow assurance for removal of scale, organic deposition

- Sustain of production with water shut off and sand consolidation

- Diagnostics using SPECTRUM® real-time solutions

COILED TUBING SERVICES

Use of fiber optics-enabled coiled tubing

Real-time coiled tubing services combine intervention and diagnostics to monitor and optimize job performance.

SEE DATA SHEET

Electric and fiber optic real-time coiled tubing

Halliburton is committed to providing superior technology and cutting-edge research with the best customer service in the coiled tubing industry.

02:51

SPECTRUM® real-time coiled tubing services

See products below

SPECTRUM® FUSION

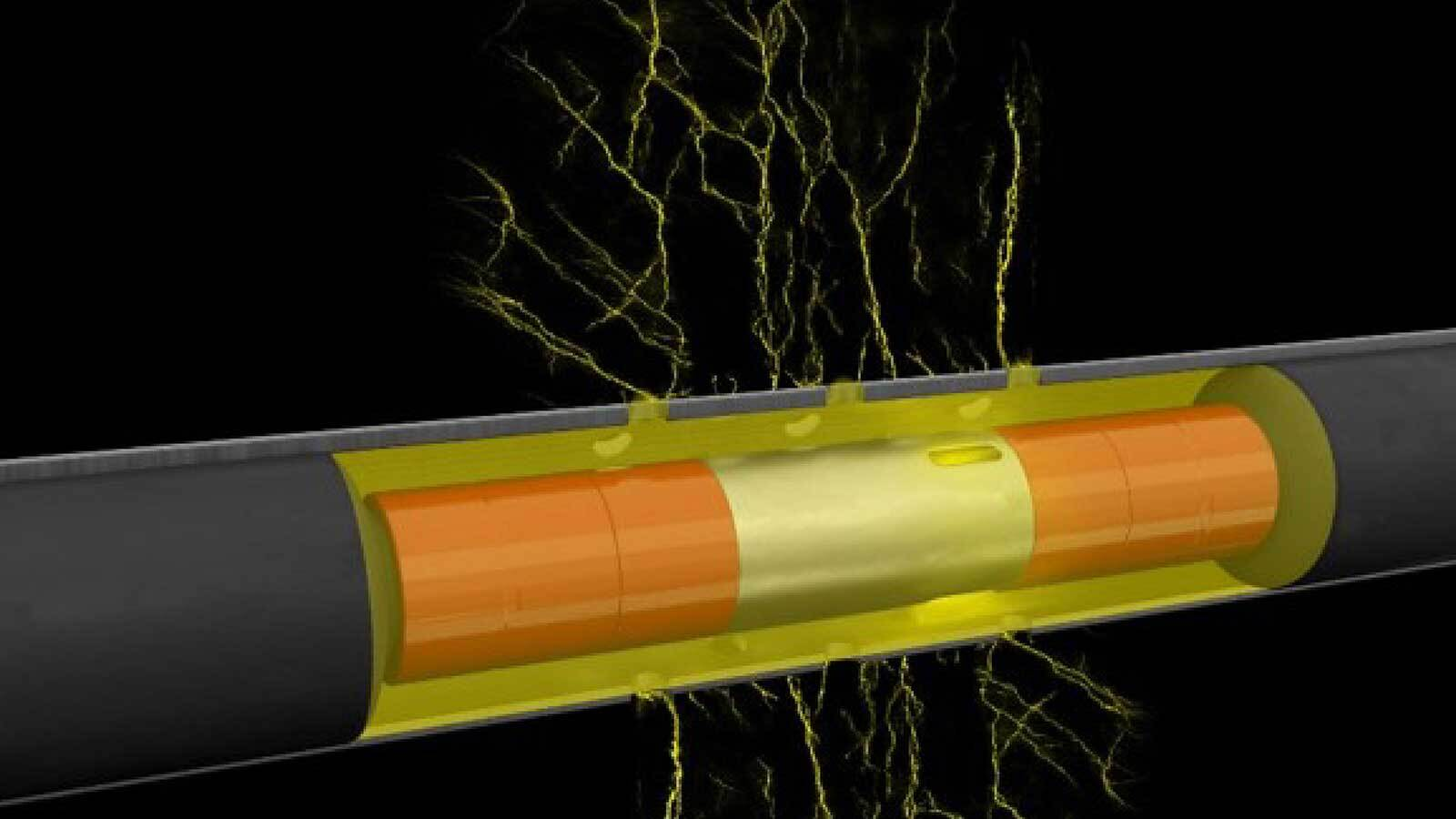

SPECTRUM® FUSION real-time hybrid coiled tubing service is a step-change in the industry by integrating fiber optic and electric communication and power.

SPECTRUM® 360

SPECTRUM 360 is the industry’s first flow through multi-side view camera, providing downhole visualization of well intervention services.

SPECTRUM® e-IP

SPECTRUM e-IP is an inflatable isolation tool equipped with a unique electric actuation system that delivers unmatched treatment precision.

SPECTRUM® IRIS

SPECTRUM IRIS is a real-time high-resolution down-view camera with full circulation capabilities.

SPECTRUM® e-MLT

SPECTRUM e-MLT is a real-time coiled tubing technology to effectively and precisely intervene in multilateral wells.

SPECTRUM® e-ORIENTER

SPECTRUM e-ORIENTER offers a new level of precision for downhole orientation.

Onshore coiled tubing equipment

Mature fields - Maintaining production on aging assets is a constant challenge, with flow assurance and well integrity issues being the largest culprits preventing wells from producing at their maximum potential.

Halliburton Production Solutions has the right equipment for the job, from smaller capillary tubing units and body load style coiled tubing mast units to larger more conventional coiled tubing units.

Mast units - On locations with limited space or fast-paced operations where a crane is not practical, a stand-alone coiled tubing unit can provide a tremendous operational advantage.

Enhanced quick rig unit - Get the work done in a record time with Enhanced Quick Rig (EQR) units.

Unconventionals - The unconventional revolution in the oil and gas industry has seen coiled tubing equipment grow from smaller units traditionally used for well intervention, to massive units with large pipe capacity.

As lateral length and stage density continue to increase, having a coiled tubing unit that can reliably reach total depth while still being able to navigate roads and permitting restrictions is crucial to completing a well. Halliburton Production Solutions has the right equipment to meet our customer's unconventional challenges.

High capacity coiled tubing units - Halliburton has high capacity coiled tubing units in every major unconventional basin, helping our customers meet their unconventional completion challenges.

High capacity coiled tubing reels - When transporting the reel with the unit is not an option due to road conditions or regulations, we have alternative separate reel solutions.

COILED TUBING JOB DESIGN USING IWI SOFTWARE

InSite® for Well Intervention (IWI)

A robust modeling tool to create customized solutions for specific intervention challenges.

With wells becoming deeper, more highly deviated, and complex, the need for accurate coiled tubing design and analysis is becoming even more critical. Hydraulics and mechanical forces can be analyzed in greater detail prior to any operation to ensure the likelihood of a successful job or assess overall feasibility.

LEARN MORE

Offshore coiled tubing equipment

Deepwater - Deepwater is always full of challenges. Between rig space limitations, hazardous area requirements, and complex well completions, specialized equipment is often needed. Our technology, rigorous processes, and experienced personnel are here to make you successful.

Hazardous area equipment - When the only place available is classified as a hazardous area, Halliburton has unique equipment to ensure the job is done safely and effectively.

Shelf/small platform - Halliburton Production Solutions has ideal equipment to meet these challenges. and help ensure offshore assets are producing to their maximum potential.

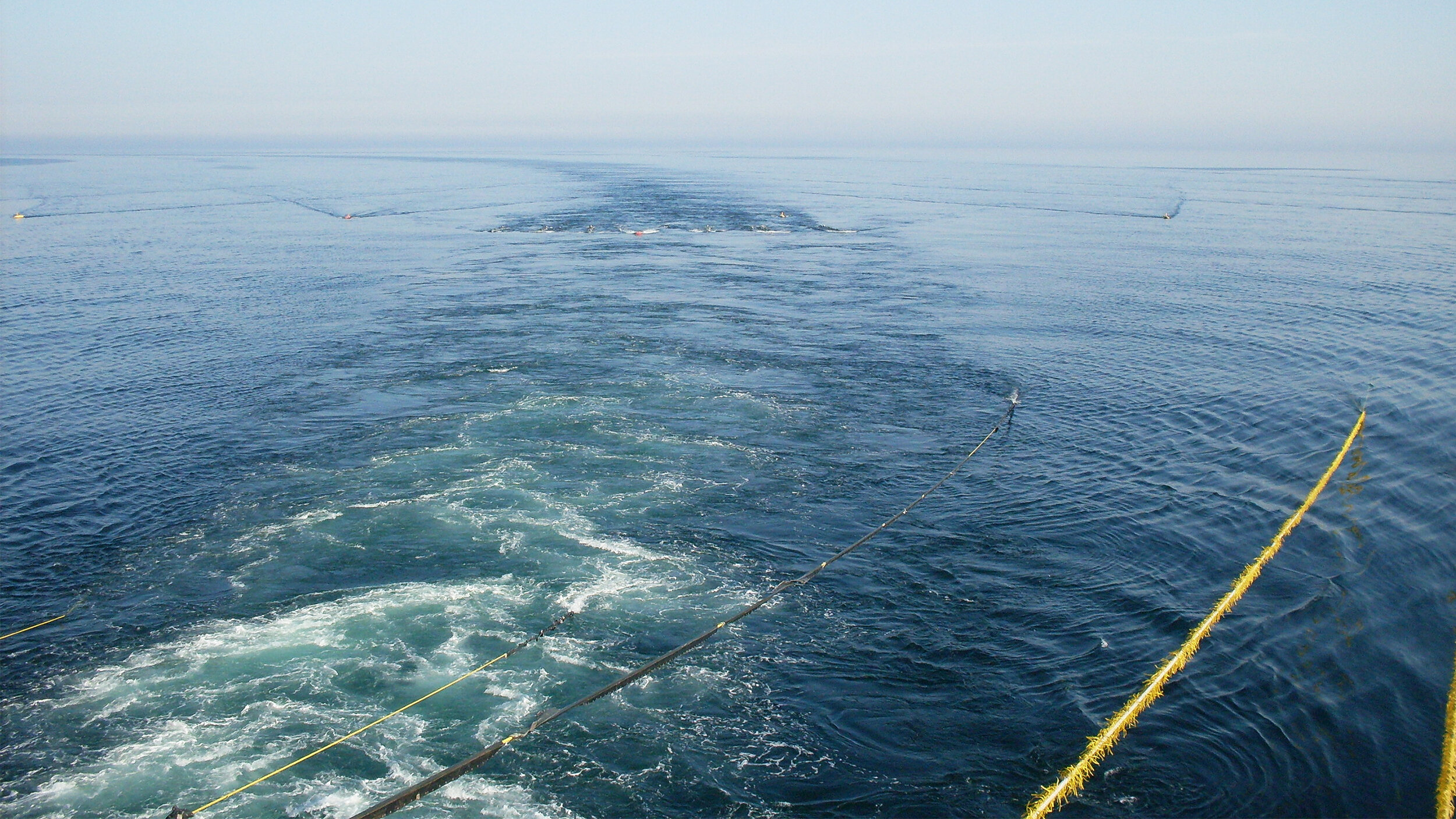

Catenary barge coiled tubing - The catenary barge offers the ability to perform coiled tubing well interventions from a support vessel – with only limited equipment being placed on the platform.

Compact footprint equipment - With limited deck space availability, having equipment that can fit in tight spaces is crucial. Halliburton has stackable offshore CT equipment to meet the demands of tight offshore spaces.

Subsea - The subsea environment is one of the most challenging environments. The coiled tubing downline system can perform work on subsea infrastructure or bullhead treatments into subsea wells without the requirement of a rig.

Coiled tubing downlines - From flowline cleanout in over 9,000 ft of water to bullheading treatments, we have the equipment and expertise to address subsea challenges.

Explore Halliburton offshore coiled tubing equipment

Catenary coiled tubing operations

With the use of a catenary services, Halliburton can perform coiled tubing well interventions from a support vessel.

Subsea Coiled Tubing Downlines

Subsea coiled tubing downlines services offers a rigless deepwater operation option to save costs and operational time