well-intervention-and-diagnostics - subsea-safety-system

Subsea Completion and Intervention

Halliburton offers innovative subsea safety systems for applications in exploration and appraisal, completion, and intervention.

Subsea expertise

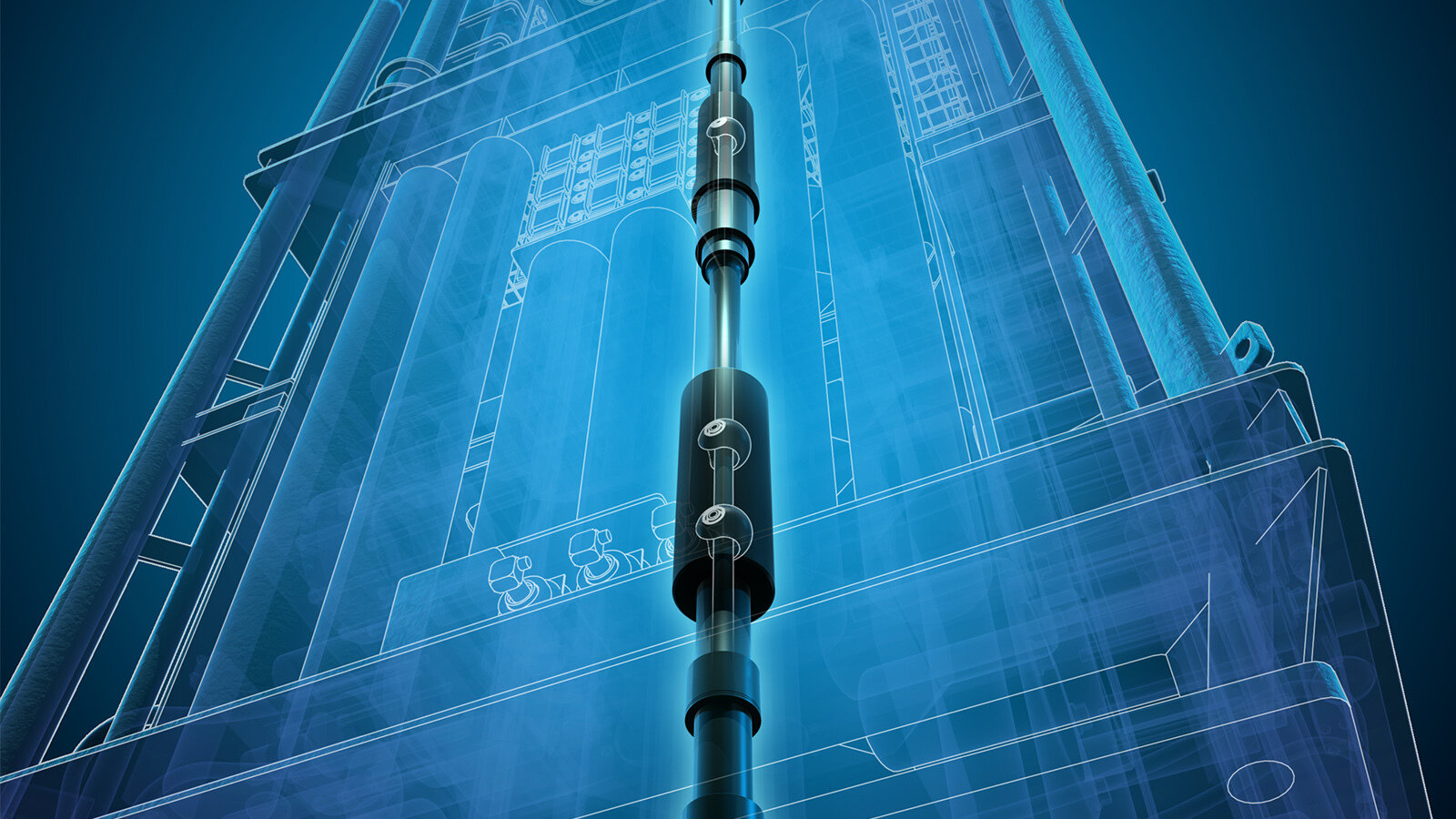

The latest advances in design and technology are built into our subsea solutions, based on unique Halliburton and alliance partnership technologies: Veto™ and Dash® Subsea Safety Systems, ROCS umbilical-less completion landing string, SCILS subsea controls, and LWIS well access system.

As the industry continues its commitment to access global oil and gas reserves in safe, environmentally sensitive ways, Halliburton leads in designing subsea solutions that are reliable, cost-effective, and safe.

SUBSEA WELL INTERVENTION

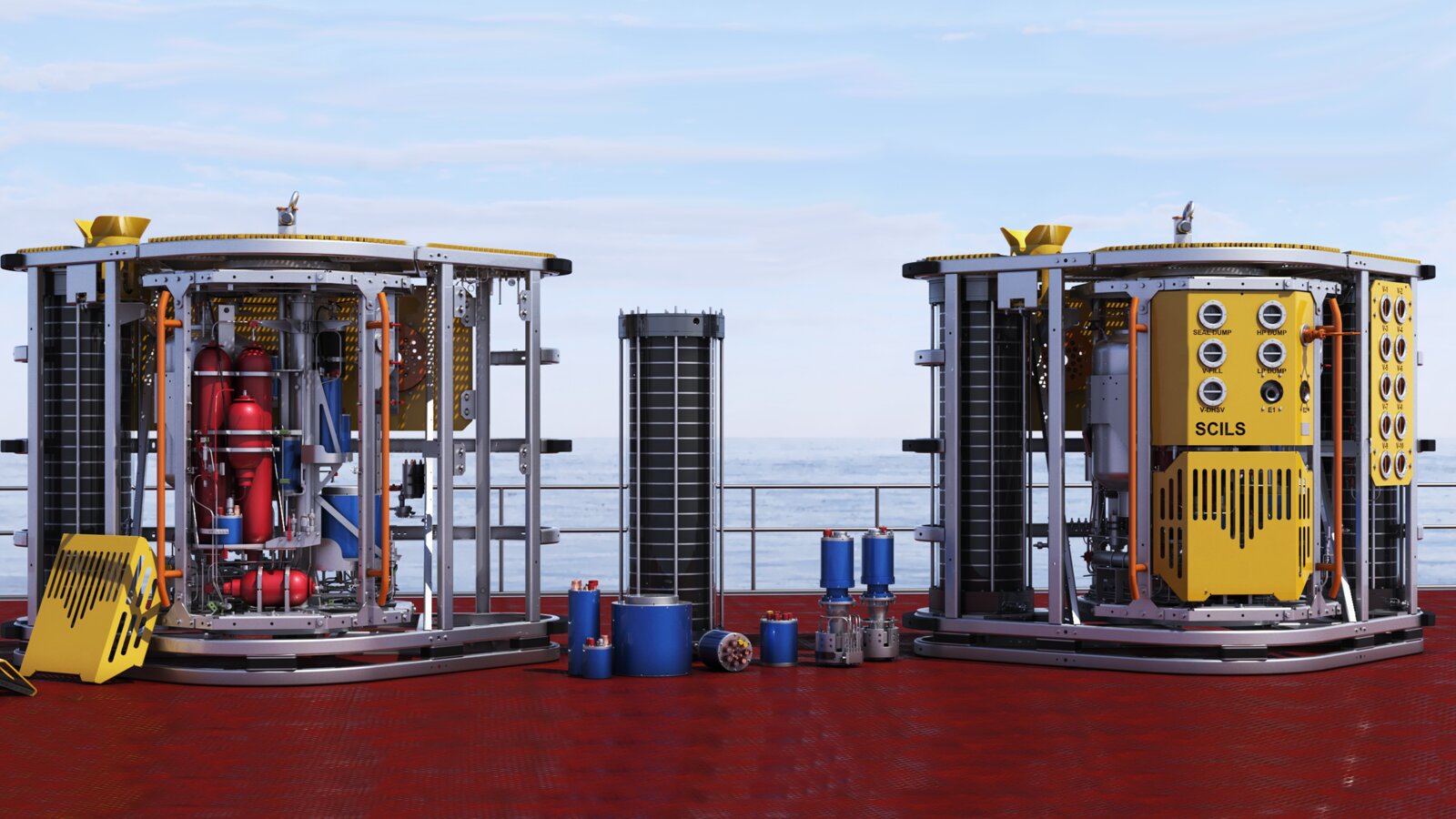

Intervention Workover Control System (IWOCS)

- Subsea Hydraulic Control

- Subsea Production Tree installation

- Interventions & Workovers

- Plug & Abandonments

- Back-up Subsea HPU

LEARN MORE

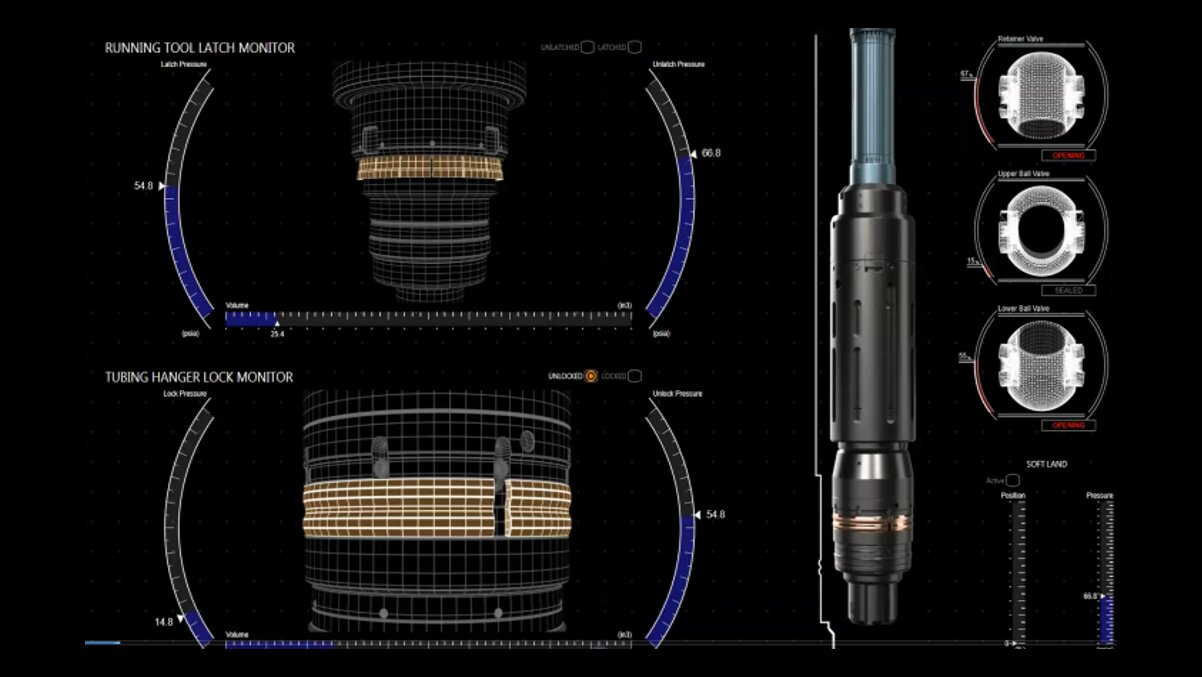

HMI CONTROLS

Increased Efficiency

- Simulate control to perform emergency well shut-in on landing strings

- Immediate input and output verification

- Full integration with surface and downhole controls

- Lowers complexity of system

Completion & Intervention

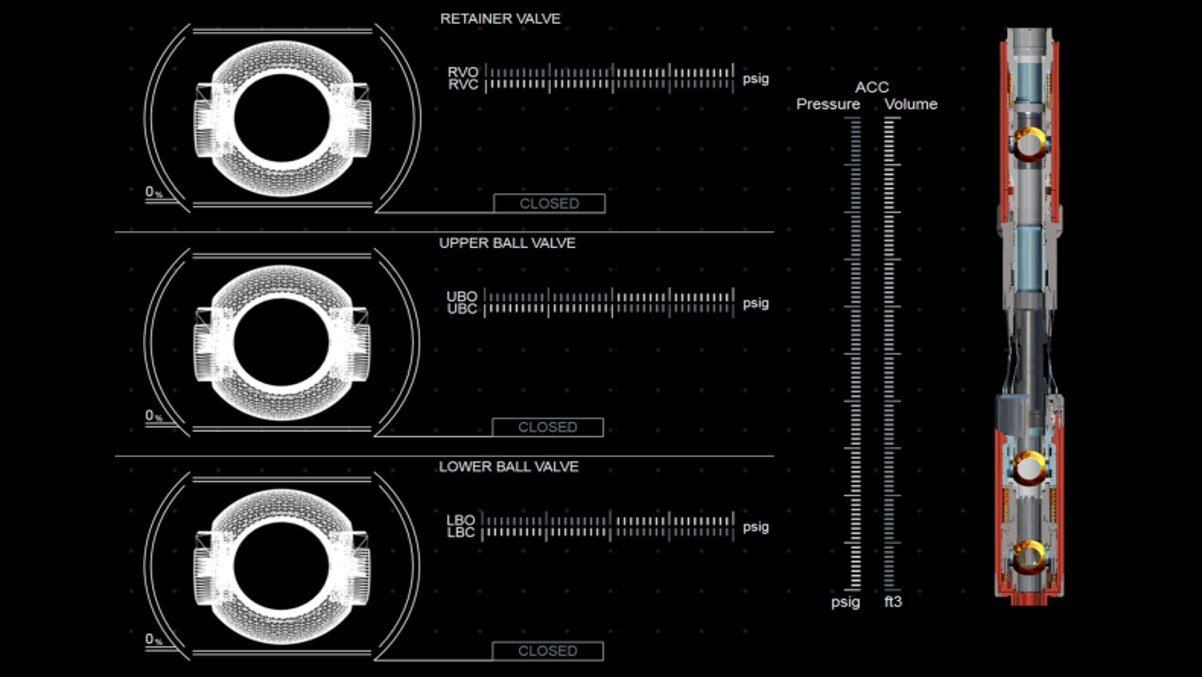

Subsea safety systems during completions and well interventions provide a critical barrier to the well in the event drift-off/drive-off or well-control issues arise. The large-bore systems are run with either horizontal or vertical trees and integrated with the tubing hanger running tool to enable control of the upper completion.

Subsea Safety System Technologies

Veto™: Halliburton fills all completion landing string needs with Veto™ 6 ( 6-3/8-in. system rated to 15,000 psi), and Veto 7 (7-3/8-in. ID system rated to 10,000 psi). Both are direct hydraulic, dual-barrier systems consisting of a lubricator valve, retainer valve, and subsea safety tree.

Dash® Large Bore Electrohydraulic Subsea Safety Systems: Dash delivers industry-leading response times, isolating the well in as little as six seconds and disconnecting from the seabed in four seconds for a total emergency disconnect in 10 seconds.

|

|

6-3/8-in. Bore 15,000 psi |

7-3/8-in. Bore 10,000 psi |

|

|

Direct Hydraulic |

Veto 6 System |

Veto 7 System |

|

|

Electrohydraulic |

Dash 6 System |

Dash 7 System |

SUBSEA WELL INTERVENTION

Open Water Well Access Systems

- Operations from a Rig or Vessel

- Well Interventions Riser or Riserless

- Light Well Intervention System (LWIS), Completion Workover Riser System (CWOR)

LEARN MORE

SUBSEA WELL INTERVENTION AND COMPLETIONS

In-Riser, Completion Landing Strings

- Rig Operations with BOP

- Installation of Completions, Flowbacks, Interventions

- Simplified Landing Strings

- Direct Hydraulic systems

- Electrohydraulic systems

EXPLORE A CASE STUDY

Related Solutions

Subsea Exploration & Appraisal

Subsea safety systems are critical to maintaining the highest level of safety for personnel and equipment during well-testing operations.